Guidelines for the Production and Use of Evidence Based Locally Made Reusable Face Masks

Please note that the evidence-based locally made reusable face masks referred to below should be worn as a preventive measure by Nurses, Nurse-Midwives, healthcare workers, and non-covid patients they come into contact with. When caring for covid positive patients, N95 masks should be worn.

1. Material Specifications

Recommended fabrics: AAN recommends using woven fabrics made from 100% polyester with a sateen/satin weave design and tight weave density, or 100% nylon with a sateen/satin weave design and tight weave density. These fabrics are recommended because their weave design and density increase resistance to fluid penetration and reduce the level of penetration of microorganisms.

Important Note: Cotton is an inappropriate fabric for face masks because it absorbs and allows for transmission of the virus contained through the material.

Important Note: Improvised filters are not appropriate.

2. Material Procurement

2.1 Weave design identification guidelines: Using a magnifying glass, follow one warp thread (vertical) or one weft thread to determine if the order of interlacement (weave design/pattern) is one over, four under (a sateen weave design), or one under, four over (a satin weave design).

No

No

Yes

2.2 Fabric purchasing: Engage a skilled textile expert in the identification and purchase of mask-making fabrics. Skilled experts can be engaged from local training institutions (universities, Technical colleges, etc.) with relevant departments, or from textile vendors with good textile knowledge.

3. Production Specifications

3.1 Production Room Cleanliness: Prior to making reusable masks, ensure the production room is cleaned thoroughly with soap and water, and the surfaces in contact with mask-making materials are sterilized using household bleach.

Tailors and those responsible for handling and packaging the masks should themselves be masked throughout the process of their work and should wash their hands thoroughly with soap and water prior to touching the fabrics, production tools, workspaces, and finished products.

3.2 How to locally produce a reusable medical face mask.

3.2.1 Each mask should be made of three rectangular panels, with the exterior panel slightly larger than the interior ones, in order to fold back the edges of the exterior panel over the interior ones and machine stitch across the inside edges of the mask.

3.2.2 Use nylon or polyester thread for all stitching.

3.2.3 Cut two equal-length elastic material bands.

3.2.4 Machine stitch these to the mask with tight, close stitches.

Alternatively, you can make a “tunnel” when folding and stitching the larger outer layer to the inner layer, so that the elastic material band moves freely.

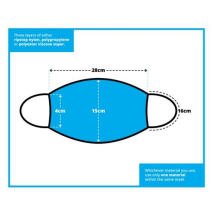

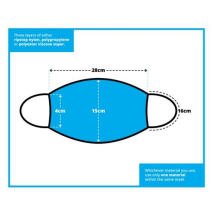

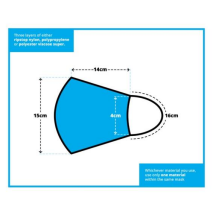

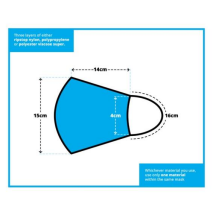

3.3 Diagrams and measures.

This is a basic design for a face mask, the aim of which is to cover the nostrils, the mouth, and the chin. Similar designs that achieve this with dimensions adjusted for local relevance are also acceptable.

3.4 Mask Sterilization: After production, masks should be sterilized through either boiling in water for at least 30 minutes, soaking in a solution containing 1 cup (240 ml) of household bleach to 20 liters of water for 30 minutes, or exposure to

heat at temperatures greater than 70 degrees Celsius for 30 minutes.

4. User Instructions

4.1 Putting on the mask: Wash your hands with water and soap for twenty seconds, or with hand sanitizer containing 70% alcohol by rubbing your hands together thoroughly for twenty seconds. Take 5 deep breaths in a safe location, then put on the mask.

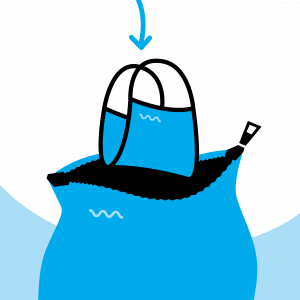

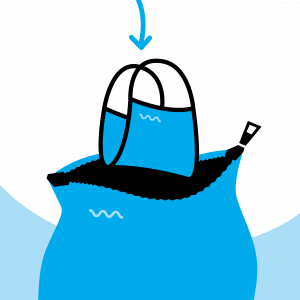

4.2. Taking off the mask: Wash your hands with water and soap for twenty seconds, or with hand sanitizer containing 70% alcohol by rubbing your hands together thoroughly for twenty seconds, then take off the mask and drop it in the washing container or face mask bag. If you are taking off the mask to eat then you should wash your hands using soap and water for a minimum of 20 seconds, seeing as hand sanitizer and similar anti-bacterial products should not be ingested.

4.3. Washing the mask: Wash the mask after use, daily. Wash the mask by hand with hot water and soap for at least 60 seconds. Dry the mask inside your residence, preferably by hanging it in the sunlight.

3.4.4.4. Storing the mask: Store the mask in a closable pouch, ideally made of the same material as the mask is made of.

4.5. Life span of the mask: Use the mask until there is visible evidence of wear on the surface of the mask.

4.6. Disposing of the mask: Dispose of the mask as you would any other contaminated materials in a healthcare setting.